Frequently asked questions are organized into sections addressing (i) methods and results, (ii) comparing this work to other studies, and (iii) interpreting the results.

| |

Methods and Results

|

| |

What is a pneumatic controller? |

| |

[+] Answer

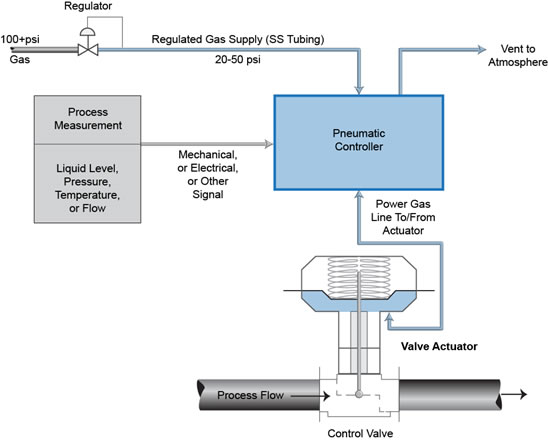

Pneumatic controllers use gas pressure to control the operation of mechanical devices, such as valves. The valves, in turn, control process conditions such as levels, temperatures and pressures. When a pneumatic controller identifies the need to change liquid level, pressure, temperature or flow, it will open or close a control valve. When a pneumatic controller opens or closes a valve, gas is released. If the controller uses natural gas as its supply gas, methane is emitted when the gas is released. A conceptual diagram showing a pneumatic controller and the valve it controls, is shown below.

|

| |

|

|

| |

Do all pneumatic controllers operate in similar ways and have the same types of emissions? |

| |

[+] Answer

When a pneumatic controller opens or closes a valve, the valve's position can be adjusted either through discrete (on/off) changes, or through changes that are proportional in magnitude to the deviation from the set point (throttling). Controllers can deliver this type of service (on/off and throttling) through either continuously venting or intermittent venting of gas. Thus, controllers can be grouped into four categories, depending on the type of service (on/off or throttling) and the type of venting (continuous or intermittent). In estimating emissions, the U.S. EPA uses the categories of low continuous bleed (<6 scf/h of gas vented), high continuous bleed (>6 standard cubic feet per hour (scf/h) of gas vented) and intermittent controllers.

In addition to categorizing pneumatic controllers by their mode of operation and whether their emissions are intermittent or continuous, controllers can be categorized based on equipment manufacturer, model number, and the type of application (e.g., separator level control) in which they are used. In this measurement study, controllers were primarily categorized as either continuous vent or intermittent vent based on the emission pattern observed during measurement; data on applications, service types, and EPA categorization for the controllers are also provided.

|

| |

|

|

| |

Why was the study done and what is unique about the methods used and data reported in this study? |

| |

[+] Answer

Previous analyses of pneumatic controllers (Allen et al., 2013; PNAS, 110, 17768-17773) had indicated that average emissions per controller were larger than expected. The goal of the study was to better understand pneumatic controller emissions. The features of this study are:

- A unique partnership: Study design, data, and findings were all reviewed by the study team, Environmental Defense Fund, participating oil and gas companies, and an independent Scientific Advisory Panel.

- Direct access: Participating companies provided access to wells with pneumatic controllers, and assisted in the design of safe sampling protocols, making possible measurements of emissions directly at the source.

|

| |

|

|

| |

What types of pneumatic controllers were sampled? |

| |

[+] Answer

A total of 377 pneumatic controllers were sampled at 65 sites (some with multiple wells) throughout the United States (an average of 5.8 pneumatic controllers per site, 2.7 controllers per well). Measurements were made primarily at natural gas production sites (351 of 377 controllers), and at a limited number of oil sites (26 controllers). Because the definitions of oil and gas wells vary, largely depending on gas to oil production ratios, the data are treated as a single set. Sampling sites were selected randomly from well sites owned by companies participating in the study. For each well site that was visited, all controllers on the site were sampled, unless operating conditions, safety issues or other factors prevented sampling. The controllers were used in a variety of applications (e.g., separator level control, compressor pressure control). |

| |

|

|

| |

How were sites selected for sampling? What steps were taken to eliminate bias in the sites sampled? |

| |

[+] Answer

Sampling of pneumatic controllers was conducted in four major regions (Appalachian, Gulf Coast, Mid-continent, Rocky Mountain); based on current characterizations of pneumatic controller design types (continuous vent or intermittent vent, on/off or throttling), it was anticipated that several types of controller designs would need to be sampled; it was also anticipated that there would be multiple types of controller service (e.g., separator level control service) that would influence actuation frequency and other parameters that affect emissions. To sample regions, controller design types and controller service types, it was anticipated that approximately 350-400 devices would need to be sampled.

Data from EPA's Greenhouse Gas Reporting Program (GHGRP, Reporting Year 2012) were used to identify the basins where the ten participant companies had reported pneumatic emissions. Based on this distribution of available basins in which to sample, the study team selected at least two companies to sample in each region (Appalachian, Gulf Coast, Mid-continent, Rocky Mountain), such that all ten participant companies were sampled. None of the companies refused a site visit. Where possible, the study team selected basins that produced a mix of device design and service types, rather than visiting sites that reported only one device type. The Study Team was solely responsible for the selection of regions and basins in which to sample.

Once basins and companies to be sampled in each basin were selected, 2-3 day site visits were planned. In each of these site visits, the focus was on sampling well pads for a single company in a single basin. Thirteen of these 2-3 day visits were conducted. Local contacts for participant companies provided descriptions or lists of the well pad sites or central facilities (e.g. sites with separators for multiple wells) in the area to be sampled. The study team selected the sites; all sites identified by the local contacts were available for sampling; depending on the distances between sites, the study team either randomly selected sites or selected sites that were relatively proximate to the starting location, so that a relatively large number of samples could be made without losing efficiency due to long travel times between pad locations. The goal was to sample a cross section of typical facilities. If a company had a mix of old and new facilities, or acquired and company built facilities, the study team selected pad types in proportion to the population in the area.

Once at a site, the Study Team measured emissions from all pneumatic devices at the site, unless safety or operational issues or lack of access prohibited sampling. This was done to achieve a sample population that would represent controller service and design types currently in use.

|

| |

|

|

| |

Are the raw data publicly available? Are any data not being released? |

| |

[+] Answer

The full dataset is available and more information can be found at the web site of the Cockrell School of Engineering at the University of Texas at Austin:

http://dept.ceer.utexas.edu/methane2/study

All of the measurement data collected during the study are available in the publicly available study reports and dataset.

|

| |

|

|

| |

Why focus only on methane? |

| |

[+] Answer

Much uncertainty exists about the amount of methane emissions resulting from natural gas production activities, such as the operation of pneumatic controllers, and the focus in this work was on resolving that uncertainty, using direct measurements of emissions at the source of the emissions. Natural gas exploration and production operations can produce a variety of emissions. Expanding the chemicals targeted for measurements would have significantly expanded the scope and complexity of the study. |

| |

|

|

| |

Why make measurements in different regions and why would emissions vary from geologic basin to basin? |

| |

[+] Answer

The study team made measurements in the Appalachian, Gulf Coast, Mid-continent, and Rocky Mountain regions. Differences in the geological formations that are the source of natural gas and condensates can lead to differences in operating procedures. For example, differences in liquid production rates can lead to differences in the frequencies at which controllers open the valve between separators and water or oil tanks, changing emissions. Overall, regional differences in emissions from pneumatic controllers are due to a variety of factors including differences in geological formations, differences in the types of controllers installed, differences in operating practices and differences in regulations. |

| |

|

|

|

Comparing this work to other studies

|

| |

How do these the emissions per controller compare to emissions reported by the U.S Environmental Protection Agency? |

| |

[+] Answer

The average emissions per controller measured in this work was 4.9 scf methane/hr. The average emissions per controller reported in the 2012 EPA national greenhouse gas emission inventory (2012 GHG NEI, released in 2014) is 4.2 scf methane/hr. |

| |

|

|

| |

How do national emission estimates for pneumatic controllers based on this work compare to emissions reported by the U.S Environmental Protection Agency? |

| |

[+] Answer

If average emission rates per controller determined in this work are multiplied by controller counts reported in the 2012 EPA national greenhouse gas emission inventory (2012 GHG NEI, released in 2014), the national methane emission estimate for pneumatic controllers in natural gas service is 313-394 Gg/yr (the 2012 GHG NEI estimate is 334 Gg).

This estimate may represent a lower bound on national emissions, however, since the average number of controllers per well observed in this work (2.7 controllers per well) was higher than the average number of controllers per well (1.0 controllers per well) reported in the 2012 GHG NEI, potentially indicating an under-count of controllers in the GHG NEI. Some of the difference between the controllers per well observed in this work and the average pneumatic controllers per well in the GHG NEI is due to wells that use mechanical or other non-pneumatic controllers; another reason for the difference is the count of controllers per well in this work includes some low emitting devices that may not be included in the count of national controllers.

If it is assumed that approximately 75% of the gas wells in the United States have pneumatic (as opposed to mechanical) controllers, and that 75% of the controllers on an average site are inventoried (as opposed to devices such as emergency shut-down controllers, which may be excluded from counts due to low probability of actuation) then a central estimate of emissions for pneumatic controllers is 600 Gg/yr, however, because of the uncertainty in numbers of controllers, this estimate has large uncertainty. It was beyond the scope of this work to develop new national pneumatic controller counts, but the data reported here indicate that this is a topic that merits attention.

|

| |

|

|

| |

How do these results compare to emissions reported by Allen et al. (2013; PNAS, 110, 17768-17773)? |

| |

[+] Answer

The overall average emission rates per controller reported in this work are lower than the previous data sets reported by Allen, et al. (2013) for the United States, and for data collected in British Columbia and Alberta in late 2013. For the British Columbia data this can be attributed to the sampling design for that data set, which selected devices with manufacturer reported bleed rates in excess of 4.2 scf/h. These controller types tend to be found in particular applications. When the emissions from the British Columbia data set are compared to the emissions reported in this work, for devices in similar applications, the results are in reasonable agreement.

The lower average emission rates per controller reported in this work, compared to those reported by Allen, et al. (2013) is primarily due to the number of controllers with low or no emissions detected over the sampling period. This could be due to multiple factors. In this work, all controllers on-site were sampled, regardless of whether they would be reported through emission inventories. For example, Emergency Shut-Down (ESD) controllers represented 12% of the sampled population in this work. These controllers do not have planned actuations, so they would not have been sampled in the work of Allen, et al. (2013), and they may or may not be included in controller counts in national emission inventories. In addition, in the work of Allen, et al. (2013), only horizontal wells that had been hydraulically fractured were sampled. Controllers on these wells have higher emissions, on average, than the entire population of wells sampled in this work. Finally, in the work of Allen, et al. (2013) about 40% of the inventoried controllers on sites were sampled; while these were intended to be selected randomly from inventoried controllers, there may have been an unintentional bias toward devices that were observed, with an infrared camera, to have emissions.

|

| |

|

|

|

Interpreting the Results

|

| |

The study reports that 19% of the pneumatic controllers accounted for 95% of the measured emissions. Why do these controllers have high emissions? |

| |

[+] Answer

Some of the high emitting controllers had emission patterns that indicated that they were not operating as designed (e.g., a controller designed to have intermittent emissions that had continuous emissions). Other controllers were in use in applications (e.g., level control on separators) that release emissions (by actuating a control valve) with a high frequency (e.g., level controllers on separators actuated more frequently than emergency shut-down controllers). Finally, continuously venting controllers, regardless of whether they appeared to be operating as designed, had average emission rates that were an order of magnitude greater than intermittent vent controllers. |

| |

|

|

| |

The study reports that more than half of the controllers had no measured emissions during the period in which they were sampled. Are the emissions from these controllers zero? |

| |

[+] Answer

The study team made measurements for approximately 15 minutes on each controller. If an intermittent vent controller did not actuate during the 15 minute sampling period, the measured emissions were reported as zero. The annual emission for some of these controllers may be zero if the controller does not actuate for the entire year (e.g., an emergency shut-down controller). Other controllers, however, may actuate, but at a frequency less than 4 per hour (less frequently than every 15 minutes). The study team extrapolated the measured results to estimate emissions from controllers that might actuate infrequently and concluded that the emissions from these controllers might increase the reported average controller emissions by 2-11%, or less. |

| |

|

|

| |

Do these new findings change the overall emission rate, expressed as a percentage of natural gas production, reported by Allen et al. (2013; PNAS, 110, 17768-17773)? |

| |

[+] Answer

Allen, et al. (2013) reported an emission rate of 0.42% for the portion of the natural gas supply chain associated with natural gas production. This percentage was based on the estimated national emissions for 2012, divided by the total natural gas withdrawals in 2012. If the national emissions estimated in this work for 2013, including the new estimate for pneumatic controllers (600 Gg/yr), are divided by the total natural gas withdrawals in 2013, the percentage is 0.38%. The small differences in percentages between this work and Allen, et al. (2013) are due to both increased natural gas withdrawals in 2013, relative to 2012 and some small changes in emission estimates.

|